Fixed Table

- FANUC Robot / Rockwell Controls / Integrated by APT Manufacturing

- Load/Unload directly into the weld cell

- Locating holes for Fixtures to be removed and set back up in same location

- Ease of set up

- Easy maintenance and cleanliness

- Side access door for entering in a safe environment

- Small footprint

- Recipe Management with room for up to 100 recipes

- Base model is configured to weld steel (hard metal), soft metals require additional options

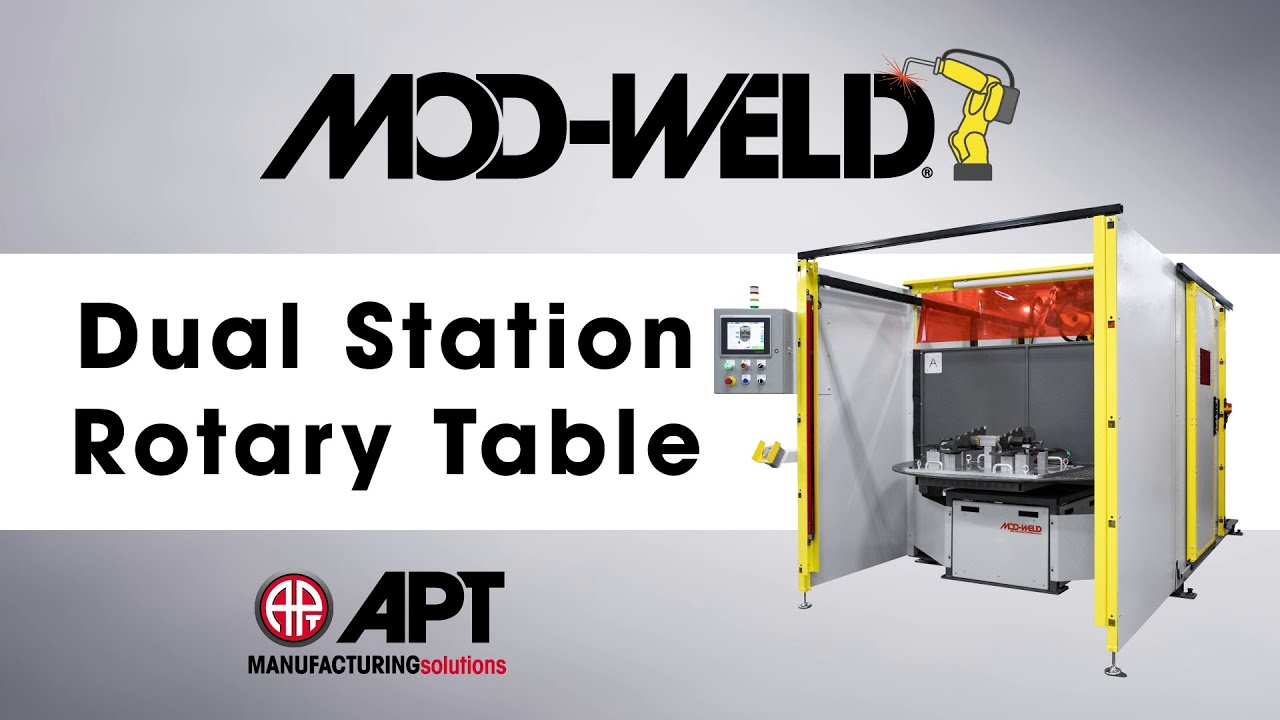

Rotary Table

Dual Station H-Frame

- FANUC Robot / Rockwell Controls / Integrated by APT Manufacturing.

- Ease of set up.

- Easy maintenance and cleanliness.

- Recipe Management with room for up to 100 recipes.

- Base model is configured to weld steel (hard metal), soft metals require additional options.

The H Frame weld cell provides a robust, efficient and high payload platform for welding a wide array of high volume components.

The rotary table allows the operator to load/unload the product outside of the weld cell, then the rotary table will bring the product into the cell for welding. When the robot has completed the welds on side “A” it will rotate table and begin welding side “B”.

The fixed table allows the operator to load the parts directly into their fixture as the robot waits in a safe position for the safety door to close before welding.

Video can’t be displayed

This video is not available.

- FANUC Robot / Rockwell Controls / Integrated by APT Manufacturing

- Load/Unload directly into the weld cell

- Locating holes for Fixtures to be removed and set back up in same location

- Ease of set up

- Easy maintenance and cleanliness

- Side access door for entering in a safe environment

- Small footprint

- Recipe Management with room for up to 100 recipes

- Base model is configured to weld steel (hard metal), soft metals require additional options