Robot Integration and Troubleshooting

-Integrate new robotic systems-Optimize exsisting programs-New part programs-Cycle time improvments-Fanuc-Yaskawa-ABB-UR

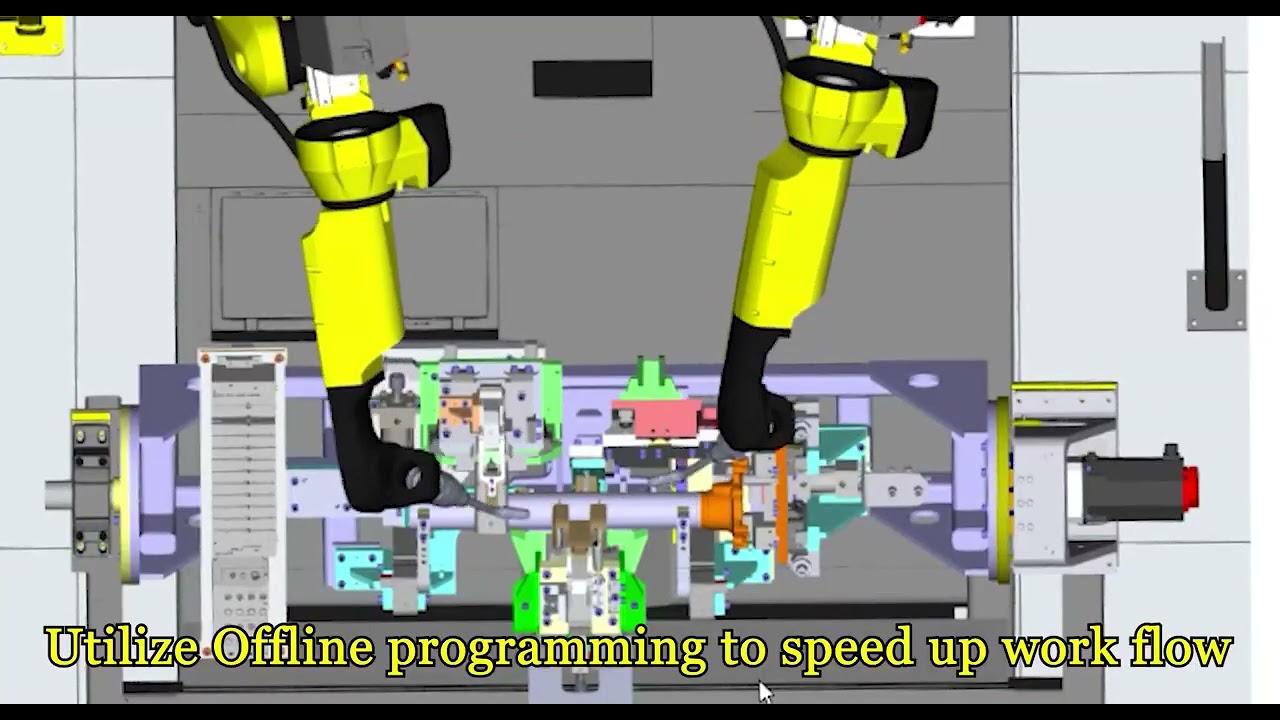

Robot and Machine Simulation

Robot simulation involves using software to model and test robotic systems in a virtual environment before deploying them in the real world.

Video can’t be displayed

This video is not available.

1. Cost Savings: Identifies potential design flaws or inefficiencies early, reducing costly modifications and downtime in real-world implementation.

2. Risk Reduction: Ability to prove out complex operations and cycle time before real-world execution and investment.

3. Faster Development: Accelerates the design and implementation process by allowing rapid testing and iteration of robot programs and equipment layout.

4. Scalability: Simulates the impact of adding new robots or modifying workflows, enabling better planning for scaling up production.

2. Risk Reduction: Ability to prove out complex operations and cycle time before real-world execution and investment.

3. Faster Development: Accelerates the design and implementation process by allowing rapid testing and iteration of robot programs and equipment layout.

4. Scalability: Simulates the impact of adding new robots or modifying workflows, enabling better planning for scaling up production.

PLC/HMI Programming and Troubleshooting

-Omron PLC -Allen Bradley PLC -Panel View Plus HMI-Pro-Face HMI-Ignition HMI

Control Panel Troubleshooting and Repair

Do you have equipment that is failing to operate as expected? Dont let electrical probleam effect your production. Give us a call today!